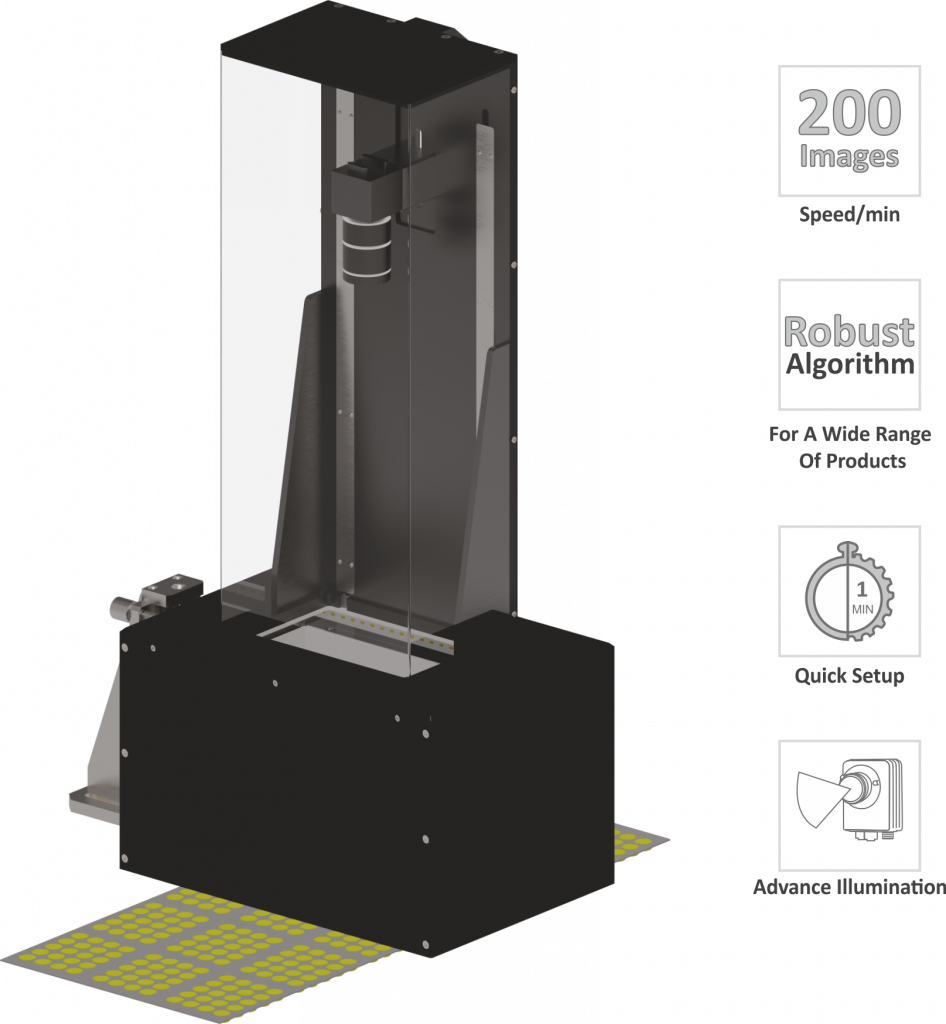

BLISS – Blister Inspection System

Introduction

Bliss – A camera-based Blister inspection system is a state of art technology developed by Propix for erroneous fillings in the blisters, which enables exact control over the quality of the product.

Bliss inspection system can detect a wide range of blister product defects and can be used on Production line for the 100% quality assurance in Pharmaceutical Industry. System is designed under cGMP guidelines.

Product Features

- 15” Touch screen with a user-friendly multilingual user interface

- Compact design to fit in all types of blister packing machines (Intermediate / Continuous type)

- High-resolution and high-speed camera along with customised optics

- State of the art reflection-free white LED based illumination suitable for all types of products

- Intelligent inspection software with strong and robust algorithm to detect different types of defects for Tablets / Capsules / Caplets on different forming layers

- Auto teach function to teach the product within 1 minute

- Smart design for ease of cleaning during product changeover

- Standard 4 tracks (optional 20 tracks) inspection with each track rejection signal output

- Max format area: 350 x 150 mm

- Encoder based trigger which eliminates camera setting and ensure accurate recipe load function

- Maintains shift register up to 151 counts. Displays live status of each product till it passes beyond rejection station

- 4 user levels & role management – Administrator, Supervisor, Operator & QA

- Various statutory reports like audit trail, product / batch wise non-editable reports

- Meets 21 CFR part 11 compliance

- Synchronized blister rejection unit with blister packing machine with rejection verification sensor

- Provision of additional Camera for 1D / 2D / Pharmacode inspection on Aluminium foil. Easily integrable with Propix Pin Hole System – Sooxma

Solution Offered

- Missing product (Empty blister)

- Wrong shape product

- Spots on products

- Color differences (Bi-color product)

- Cracked / broken product

- Oversized / undersized

- Foreign particles (Fragments)

- Detection of unwanted / wrong product

- Incorrect positioning or misalignment of the product

- Wrong code / absence of code on foil i.e. wrong foil or print defect on foil

- Inspection of batch coding details on aluminium foil

For further information please see the flyer or contact us direct!